| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | FASTPCBA |

| Model Number : | Turnkey PCB Assembly |

| Certification : | ISO13485, IATF16949, ISO9001,IOS14001 |

| Price : | Final price depends on actual order |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 100000pcs/month |

| Delivery Time : | 1-25 work days |

2 Sided Lead Free FR1 PCBA Electronics Assembly Service

Printed Circuit Board Assembly (PCBA) is one of our core services FASTPCBA. From multi-layered to flexible printed circuit boards, FASTPCBA is your one-stop shop for PCB Manufacturing + Components Sourcing + PCB Assembly + Testing, and other electronic manufacturing services companies. We provide our customers with PCB solutions and services worldwide. especially more than 80% printed circuit board are exported to oversea market. We have full of confidence to meet your quality level. Send your PCB files to get better price now !

OEM/EMS Services For PCBA:

· PCBA, PCB Board assembly: SMT & PTH & BGA

· Components sourcing and purchasing

· Quick prototyping

· Plastic injection molding

· Metal sheet stamping

· Final assembly

· Test: AOI, In-Circuit Test (ICT), Functional Test (FCT)

· Custom clearance for material importing and product exporting

Now we have been a factory which can provide one-stop service, from

the PCB production, the components purchasing to the components

assemble.

SPECIFICATIONS | CAPABILITIES | |||||||

TYPES OF ASSEMBLY | THD (Thru-Hole Device) | |||||||

SMT (Surface-Mount Technology) | ||||||||

SMT & THD mixed | ||||||||

2 sided SMT and THD assembly | ||||||||

Full Turnkey | ||||||||

Partial Turnkey/Combo | ||||||||

Consignment/kitted | ||||||||

ORDER QUANTITY | 1 to 100000 boards | |||||||

COMPONENTS | Passive Component: we can accept components as small as 01005, 0201,0402. | |||||||

Fine pitch to 8 Mils | ||||||||

BGA, uBGA, QFN,POP and Leadless chips | ||||||||

Connectors and terminals | ||||||||

COMPONENTS PACKAGE | Reels | |||||||

Continuous Tape | ||||||||

Cut tape | ||||||||

Tube and tray | ||||||||

Loose parts and bulk | ||||||||

BOARD DIMENSIONS | Smallest size: 0.2" x 0.2" | |||||||

Largest size: 15" x 20" | ||||||||

BOARD SHAPE | Rectangular | |||||||

Round | ||||||||

Slots and Cut outs | ||||||||

Complex and Irregular | ||||||||

BOARD TYPE | Rigid boards | |||||||

Rigid-Flex boards | ||||||||

ASSEMBLY PROCESS | Leaded process | |||||||

Lead-Free (RoHS) | ||||||||

DESIGN FILE FORMAT | Gerber RS-274X | |||||||

BOM (Bill of Materials) (.xls, .csv, . xlsx) | ||||||||

Centroid(Pick-N-Place/XY file) | ||||||||

SALES AND SUPPORT | Emails | |||||||

Phone calls | ||||||||

ELECTRICAL TESTING | X-ray Inspection | |||||||

AOI (Automated Optical Inspection) | ||||||||

Functional testing | ||||||||

OVEN PROFILE | Standard | |||||||

Custom | ||||||||

TURNAROUND TIME | 1-5 days for only PCB assembly | |||||||

10-16 days for turnkey PCB assembly | ||||||||

Quality Assurance

There is no shortcut for quality,and our goal just is to make well every printed circuit board. We have imported the advanced machinery from US,Japan,German and Israel to improve our production and technical ability.We have set a great example the PCB field of flying probe testing,buried and blind via and special controlled impedance. Finished PCB Assemblies are checked for proper component placement and functionality with a variety of methods including AOI Inspection, In-Circuit testing, and X-Ray inspection. We have a highly developed R&D division which has helped our factory successfully produce mechanical micro via,high density impedance and HDI.

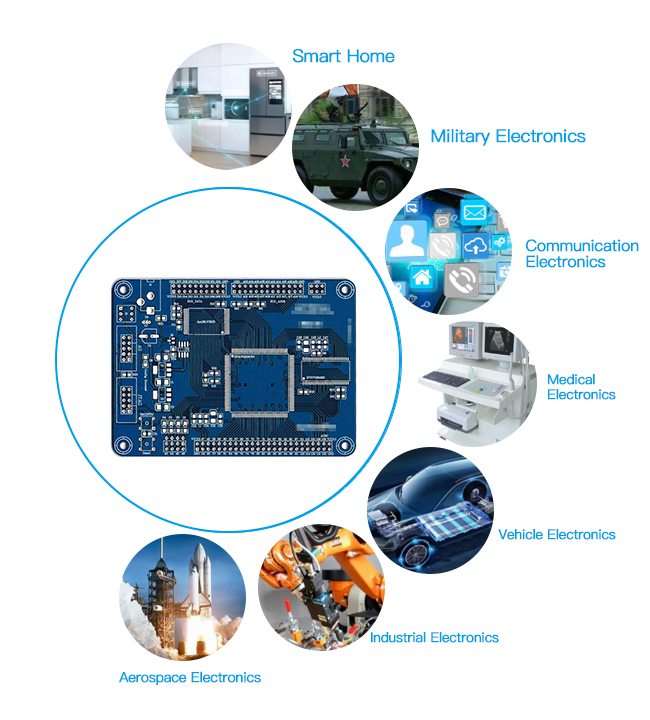

Products Application:

1, Telecom Communica

3, Security monitor

4, Vehicle Electronices

5, Smart Home

6, Industrial controls

7, Military & Defense

8, Automotive

10, Industrial Automation

11, Medical Devices

12, New Energy

And so on

A1.What is needed for PCB PCBA quotation?

PCB: Quantity, Gerber file and Technic

requirements(material,surface finish treatment, copper

thickness,board thickness ,...)

PCBA: PCB information, BOM, (Testing documents...)

A2. What file formats do you accept for PCB PCBA production?

Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

A3. Are my files safe?

Your files are held in complete safety and security.We protect the

intellectual property for our customers in the whole process.. All

documents from customers are never shared with any third parties.

A4. MOQ?

We are able to handle Small as well as large volume production with

flexibility.

A5.Shipping cost?

The shipping cost is determined by the destination, weight, packing

size of the goods. Please let us know if you need us to quote you

the shipping cost.

Send your PCB files to get better price now !

|